Our Boiler Changeout Work

D&D changes out dozens of older, failed or inefficient boilers throughout the course of a year.

Lakeshore Project History & Design Notes

Project Description

Retrofit: Radiant heating, domestic hot water and snow melt for a home at Lake Tahoe, Nevada.

History:

The radiant heating system and boilers at this home were originally installed by another contractor. The contractor made several mistakes that led to poor performance of the system and endangered the homeowner with CO buildup in the house. The original contractor had piped the radiant with a common supply and individual returns that came back to the mechanical room to zone control valves. As a result, the system was unable to evenly heat the house. The poor performance of the original contractor eventually led to a lawsuit.

A third-party mechanical engineer was asked to redesign the heating system for the home. At this point, D&D entered the job and was asked to price out the system. We priced out the system two ways: based on the engineer’s design and based on our design. Our design was lower in cost and also had several additional design enhancements. At that point, the general Contractor turned the design and the job over to D&D.

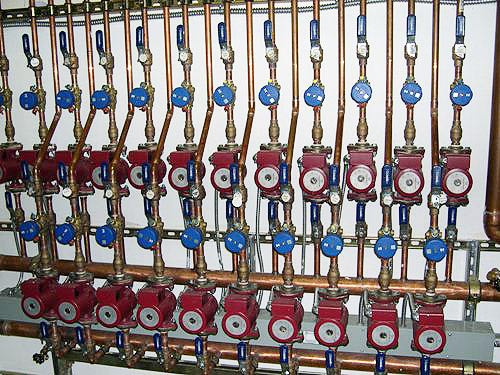

Design Notes: D&D installed two Munchkin 399s as the heart of the heating plant. The Munchkins were controlled using a Tekmar 262 boiler sequencer. In addition, the 262 was used to control the domestic hot water for the home. The system was piped in primary/secondary fashion with FlatPlate heat exchangers used to separate the boiler system from the four different heating systems. This was done because the various systems were incorrectly plumbed with domestic PEX tubing and non-barrier tubing. The FlatPlates then allowed us to use cast-iron pumps and accessories on the primary loop and boilers. One of the FlatPlates was used for the high temperature zones, one was used for the domestic hot water and the other two were used for the radiant and snow melt. The radiant and the snow melt utilized injection to temper the water. In order to ensure that adequate flow would get to each zone, we used zone pumping for the radiant and for the snow melt. The zone pumping bank can be seen in the picture below.

A Tekmar 361 injection pump control was used to control the injection for the radiant. A Tekmar 667 injection pump control was used to control the injection pump for the snow melt system. Taco SR and ZVC controls were used to control the zone pumps and zone valves.

In addition to the work at the mechanical room, we also had to make several altercations at the manifolds. The existing manifolds were homemade manifolds without any balancing devices. D&D

installed circuit setters on each loop in order to balance the flows at the manifolds.

Project Result:

As a result of all of our work on the job, all of the zones for the home were comfortable. Also the installation of the new Munchkin boilers eliminated all CO in the house.

Serene Lakes Project History & Design Notes

Project Description

New Construction:

Residential boiler installation.

Project Size:

175,000 btu/hr atmospheric boiler system that does radiant heating and domestic hot water heating.

Project Design Notes:

This was a project where the owner was doing the radiant tubing installation, and he brought D&D in to do the boiler and controls.

Boiler System:

The owner had already installed a 7” flue stack out through the roof, so we were locked into using an atmospheric boiler. We chose a highly reliable Weil McLain CGa-6.

Radiant Heating System:

The owner had installed non-barrier tubing in the floor joists with heat emission plates. As a result, we had to utilize a heat exchanger to separate the cast-iron boiler from the non-barrier tubing. In addition, the radiant zone pumps had to be stainless steel rather than cast-iron. We utilized three Tekmar thermostats, an Erie Zone pump controller and a Tekmar 361 injection controller for the control of the system. We also installed three Rehau Manifolds to connect the tubing to the distribution piping.

Domestic Hot Water System: We installed an Advance Metal 60-gallon indirect fired water heater with a double wall heat exchanger (located inside the house). The tank was equipped with an aquastat and an Erie SR100 relay was used to energize the circulating pump.